|

|||||||

The adoption of rifled artillery was a long and slow development of ideas, some impractical, in an attempt to arrive at an improved stage with acceptable accuracy. The year 1850 saw Mr. Lancaster apply for a patent for a gun with an elliptical (oval) bore with a gain twist. The use of wrought iron projectiles was inappropriate in this system as it resulted in several burst trial cannon. In 1855, both Mr. B Britton and Mr. L Thomas took out patents for projectiles with a driving band of lead or other soft material. Mr. Jeffrey produced a ‘Minie’ type cannon projectile while Mr. Hadden patented a non-expanding projectile, cast with studs, corresponding to the grooves in the bore. Many variations were tried, including one reverse design where raised ribs in the bore fitted corresponding pre-engraved grooves in the projectile. Major Vandelur, Mr. Lawrence, and Mr. B. Irving all applied their skills to the object under consideration, but the developments of Mr. J. Whitworth and Mr. W. Armstrong were considered so superior that all other designs were ignored in their favour. Parsimony of politicians, which is nothing new (except at election times), saw a Committee on Rifled Cannon appointed in 1858 to evaluate rifling of existing stocks of 32 pound smooth bore cannon of various makes. The report was totally unfavourable to the idea, because of the material used in the original founding.

Rifling in cannon had been tried in Germany as early as 1750 and also by Benjamin Robbins (1745) in England, M. Poncharra in Paris, Montigny in Brussels and again by others in St. Petersburg. Both Colonel Cavalli in Sardinia and Baron Warendorf of Sweden carried on experiments with rifling combined with ideas of breech loading. However, no practical adoption of such designs was forthcoming.

With the

introduction of rifled muskets and the Minie

ball, field artillery could not encroach within

1,000 yards with any degree of safety, but then

was far out of range for It took the French until 1856 to demonstrate the superiority of their rifled cannon in the Italian campaign against the Austrians. The Austrians hurried to obtain rifled bronze cannon based on the French system and daringly introduced gun cotton as a propellant. Russia and Sweden soon followed the trend to rifling, with Holland and Spain hot on their heels. Sardinia also tried breech loading and to their dismay it was not successful. Portugal and Switzerland rifled their muzzle loaders whilst Prussia, having access to homogeneous iron from Krupp, pursued breech loading and lead coated projectiles. The U.S.A. adopted rifling for field artillery with the Parrot system of reinforcing hoops.

|

|||||||

|

The idea of

applying rifling to field and garrison artillery

was not new in 1850. Although the range of

smooth bore muskets allowed the artillery to

engage the enemy with no danger from return

musket fire at 400 yards, the adoption of

rifling to the musket was to bring about much

concern and a desire for an increase in

artillery range. The use of rifling in cannon to

achieve this extension incurred a slower loading

time with more exposure of the gun team and was

not deemed to be as effective as rapid

discharges.

The idea of

applying rifling to field and garrison artillery

was not new in 1850. Although the range of

smooth bore muskets allowed the artillery to

engage the enemy with no danger from return

musket fire at 400 yards, the adoption of

rifling to the musket was to bring about much

concern and a desire for an increase in

artillery range. The use of rifling in cannon to

achieve this extension incurred a slower loading

time with more exposure of the gun team and was

not deemed to be as effective as rapid

discharges. engaging enemy targets. In 1856, Professor

Treadwell of Massachusetts made a recommendation

that cast iron guns could be strengthened by

encasing the barrel with hoops of wrought iron

in layers, shrunk on, to resist expansion caused

by the explosive force of a discharge. M.

Goupil had proposed this idea to the French

Government in 1833. Later this was tried by

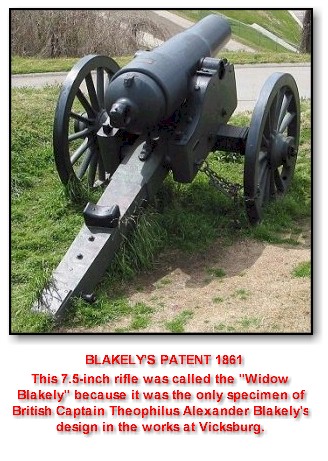

Captain Blakeley of the Royal Artillery who took

out a patent in 1855 for the manufacture of guns

with an internal tube of iron or steel enclosed

in a case of wrought iron or steel shrunk on to

the tube. Taking out a patent on an idea does

not necessarily lead to successful

manufacturing.

engaging enemy targets. In 1856, Professor

Treadwell of Massachusetts made a recommendation

that cast iron guns could be strengthened by

encasing the barrel with hoops of wrought iron

in layers, shrunk on, to resist expansion caused

by the explosive force of a discharge. M.

Goupil had proposed this idea to the French

Government in 1833. Later this was tried by

Captain Blakeley of the Royal Artillery who took

out a patent in 1855 for the manufacture of guns

with an internal tube of iron or steel enclosed

in a case of wrought iron or steel shrunk on to

the tube. Taking out a patent on an idea does

not necessarily lead to successful

manufacturing.